产品展示 product show

首页 > 产品展示| MK2110 数控内圆磨床 |

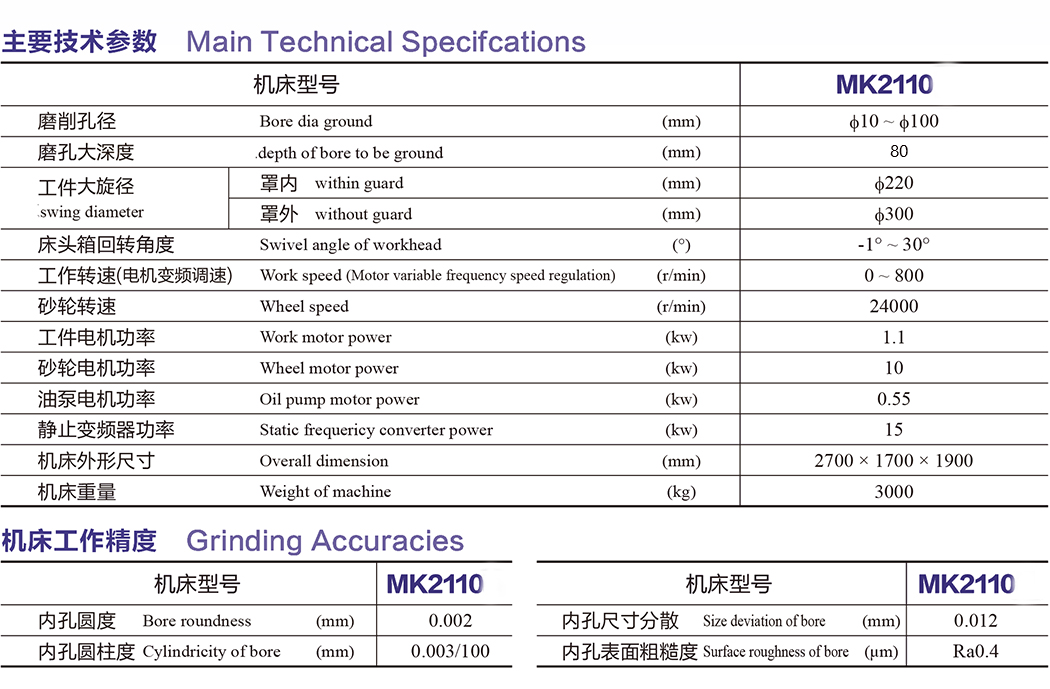

机床的主要特点 Main Characteristics: •机床床身采用铸件浇铸,刚性好,结构稳,变形小; •机床采用床头箱固定在进给滑板上工件进给,砂轮作往复结构布局; •工件进给滑板及砂轮工作台滑板采用高刚度十字交叉滚珠导轨; •工件进给由伺服电机经联轴器带动高精度滚珠丝杆副来实现,进 给和补偿为同一传动链,结构紧凑,精度高; •工件主轴采用整体套筒式主轴,刚性好,主轴轴承采用高精度成 对轴承,回转精度高,稳定性好,主轴回转变采用频无级调速; •机床配有防水全封闭罩売,观察窗长期观察清晰,耐油污并 砂轮破碎后不飞滅伤人; •机床采用后置电器箱和前置回转式操作台以及独立的循环启动按 钮。电箱带热交换器,以及确保在高温期间正常运行; •机床可根据加工零件设计制作专用夹具; •机床机床采用西门子808D数控系统,伺服单元,用户如有特殊要求可选用其他控制系统。 •The machine bed adopts the casting piece with the features of good rigidity and small deformation. •The headstock is fixed on the feed slide for achieving work feed. The gri. wheel reciprocation is also used. •Work feed guideway and gri. wheel worktable guidaway adopt the crossed roller type. •Work feed can be performed by the servo motor through the coupling via high-precision ball leadscrew pair. •Table reciprocation movement can be achieved by mechanical oscillation which its reci. speed is adjusted by the freq.-conversion speed regulator. Cartridge-type work spindle is used. The high-precision matched spindle bearing is adopted with the features of high rotating accuracy and good reliability. •Super-wide worktable and feed slide are used, thus improving good rigidity. It's totally enclosed with guards to prevent swarfs from splashing. •The rear-mounted electrical cabinet and front-mounted control cabinet are also used. The heat-exchanger in the electrical cabinet is also provided. •The special fixture can also be designed according to the machined workparts. Mitsubishi PLC control system a& servo unit is adopted. Other control system can also be selected for special order. 机床的主要结构main structure: ★本机床主要用于工件内孔,内端面,外端面,台阶子的磨削。 ★机床床身采用浇铸件,变形小,刚性好。 ★机床参数的设置,修正采用触摸屏形式,可实现人机对话。 ★机床所有移动导轨采用高精度滚动直线导轨、滑动性好,进给往复丝杠采用高精度滚珠丝杠。 ★机床进给系统和往复系统均采用伺服系统两轴联动控制。 ★机床砂轮轴采用高速电主轴,由静止变频器控制,实现无级调速。 ★床头箱工件主轴轴承采用高精度滚动轴承,工件转速为交流变频,无级调速。 ★机床可配三爪卡盘、液压卡盘、薄膜卡盘、气动卡盘等夹具供用户选配。 ★机床采用全封闭置壳,外形美观大方。 ★ This machine tool is mainly used for grinding the inner hole, inner end face, outer end face and step of the workpiece. ★The machine tool bed is made of cast parts with small deformation and good rigidity. ★ The machine tool parameters are set and corrected in the form of touch screen, which can realize man-machine dialogue. ★ All moving guideways of the machine tool adopt high-precision rolling linear guideways with good sliding performance, and the feed reciprocating lead screw adopts high-precision ball screw. ★ The feed system and the reciprocating system of the machine tool are controlled by the two-axis linkage of the servo system. ★ The grinding wheel shaft of the machine tool adopts high-speed electric spindle, which is controlled by static frequency converter to realize stepless speed regulation. ★ The spindle bearing of the headstock workpiece adopts high-precision rolling bearing, and the workpiece speed is AC variable frequency, stepless speed regulation. ★ The machine tool can be equipped with three-jaw chuck, hydraulic chuck, membrane chuck, pneumatic chuck and other fixtures for users to choose. ★ The machine tool adopts a fully enclosed shell with beautiful and generous appearance.

|

| 上一页:MBK215B 数控内圆磨床 下一页:MGK2110B 数控内圆磨床 |

|

E-mail:sales@wxhyjm.com |

E-mail:sales@wxhyjm.com |